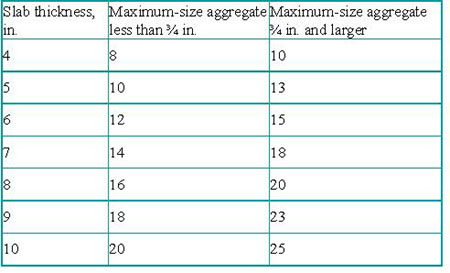

This tool provides an estimate of the maximum allowable joint spacing based on the slab thickness and the subgrade subbase used two of the variables with the most prominent effect on joint spacing requirements.

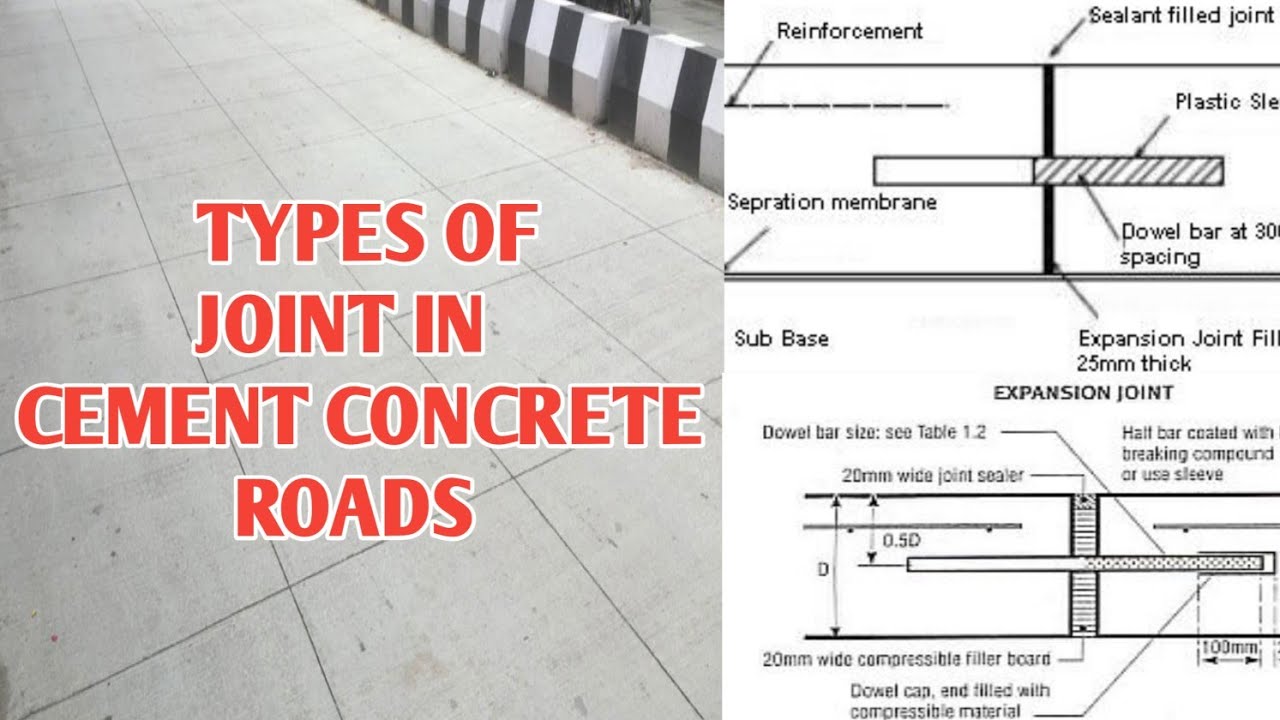

Expansion joints concrete slabs spacing.

Saw cut joints should be done within 4 to 12 hours after the concrete has been finished.

So for a slab which is 100mm thick the joints should be placed.

Joints are commonly spaced at distances equal to 24 to 30 times the slab thickness.

A 4 slab should have joints 8 12 feet apart.

Joints should be spaced about 10 feet and a maximum of 15 feet.

Usually expansion joints should be no farther apart than 2 to 3 times in feet the total width of the concrete in inches.

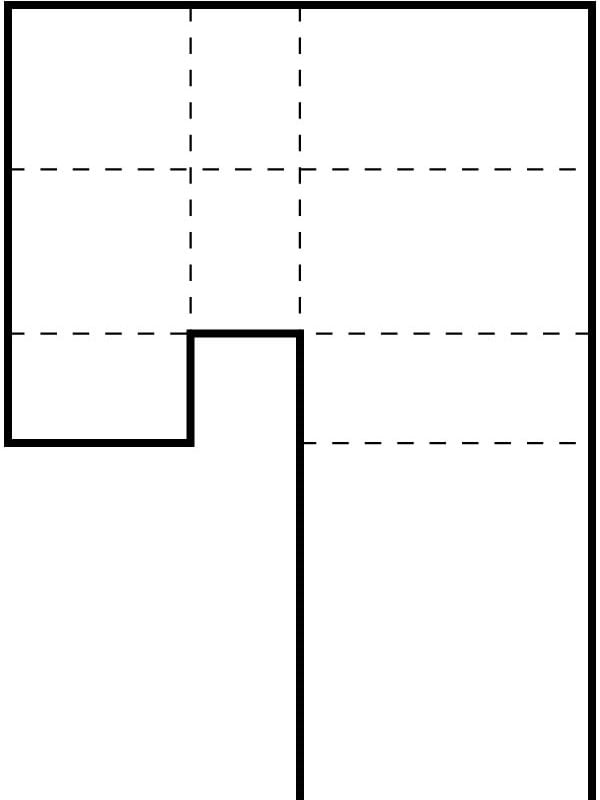

It is also important to keep slabs as square as possible.

Saw cutting cuts joints as soon as the concrete is hard enough that the edges abutting the cut don t chip from the saw blade.

Joint spacing in feet contraction joints may be tooled into the concrete surface at the time of placement.

Maximum joint spacing should be 24 to 36 times the thickness of the slab.

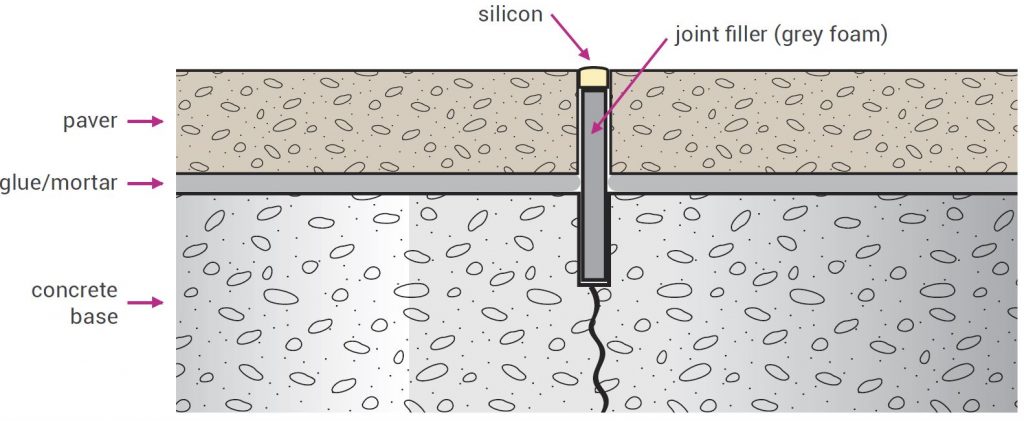

When using joint groove for contraction joints the joint should be a minimum depth of thickness of the slab.

So for a 4 inch thick concrete slab expansion joints should be no more than 8 to 12 feet apart.

Joint spacing in meters.

Transverse joint spacing should not exceed 125 to 150 of the longitudinal joint spacing.

Typically for jointed plain concrete streets the joint spacing should be 24 to 30 times the pavement thickness with a maximum spacing of 15 ft 4 5 m.

Space joints in feet no more than 2 3 times the slab thickness in inches.

Keyed joints are not recommended for industrial floors.

A 4 thick slab should have joints 1 deep.

Longitudinal joint spacing on two lane and multilane concrete pavements typically is about 10 to 13 ft 3 0 to 4 2 m.

The expansion joint gap depends on the type of slab like floating slab floor vehicle pavement sidewalk or monolithic slab foundation.

They should also be placed around structures that go deeper than the concrete slab such as columns or walls.

Cut joints deep enough cut joints 25 of the depth of the slab.

It is also influenced by the slab dimensions type of concrete and the reinforcing materials being used.

Joint spacing that is greater than 15 feet require the use of load transfer devices dowels or diamond plates.

Tips for placing concrete expansion joints place joints around 30 times the slab thickness apart.

For a 100mm slab.

Make sure joints are cut deep enough.

They need to be at least a quarter of the thickness of the slab.